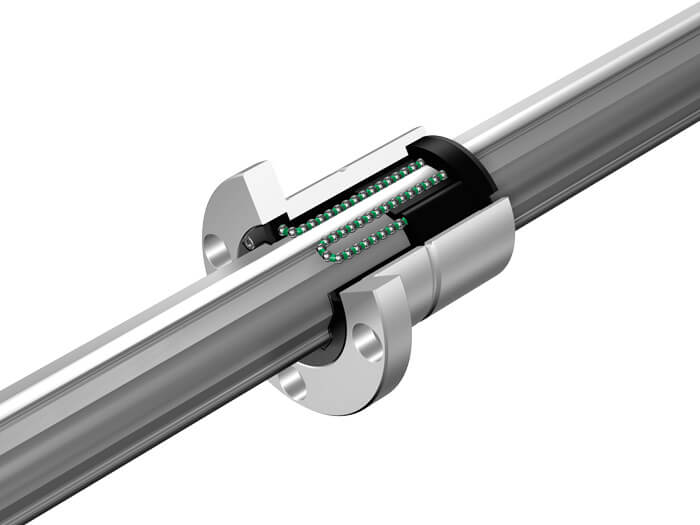

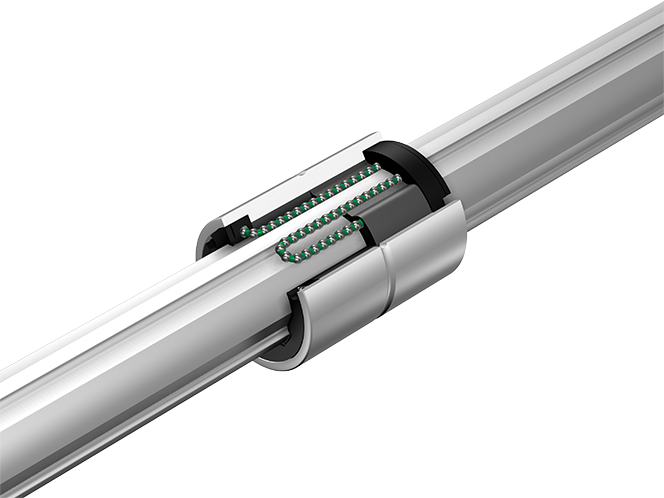

The Ball Spline is a rolling guide spline bearing. This is an innovative product with a ball rolling on a groove connected to the shaft, realizing allowable loads greater than with linear bushing and enabling torque transmission while making linear movements. The adoption of the ball cage enables the circulating motion of evenly spaced balls to be maintained and highspeed response to be achieved. In addition, it eliminates collision and mutual friction between balls, and realizes low noise, pleasant running sound and low particle generation.As the grease retention is increased, long-term maintenance-free operation is also realized. This Ball Spline has no angular backlash to increase the rigidity by providing a preload with one spline nut since the spline shaft has 3 crests equidistantly arranged at 120 degrees on the circumference, each held by 2 rows (6 rows in total) of balls under a load. This Ball Spline has a large load capacity in the radial and torque directions since the spline shaft has 2 to 3 crests on the circumference, each held by 2 rows (4 or 6 rows in total) of balls under a load in order to reasonably provide a preload. This model is a unit type that has gear teeth on the flange circumference, and radial and thrust needle bearings compactly integrated on the spline nut. This Ball Spline is optimal for a torque transmission mechanism with spline nut drive. This model is a compact unit type of Ball Spline whose support bearings are directly integrated with the outer surface of the spline nut. The integration of the ball cage enables the circulating motion of evenly spaced balls and highspeed response to be achieved. It eliminates collision and mutual friction between balls, and realizes low noise, pleasant running sound and low particle generation. With the high torque type Ball Spline, the spline shaft has three crests positioned equidistantly at 120°, and along both sides of each crest, two rows of balls (six rows in total) are arranged so as to hold the crest, as shown in Fig.1 . The raceways are precision ground into R-shaped grooves whose diameters are approximate to the ball diameter. The spline shaft has two to three crests on the circumference, and along both sides of each crest, two rows of balls (four or six rows in total) are arranged to hold the crest so that a reasonable preload is applied.

Products

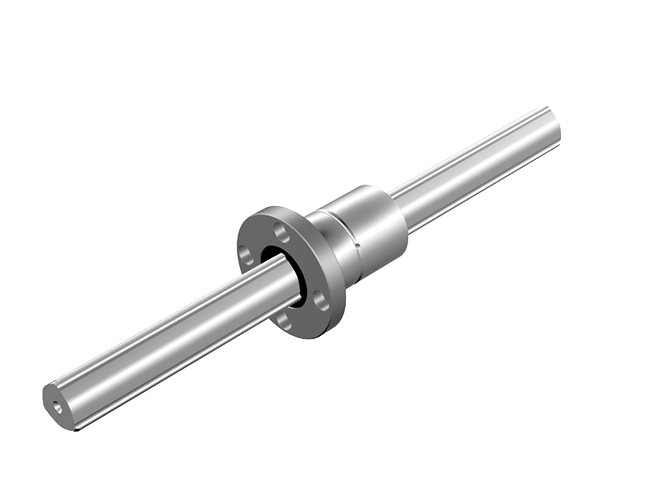

Caged Ball Spline SLS/SLF

Model Number(s)

SLS/SLF

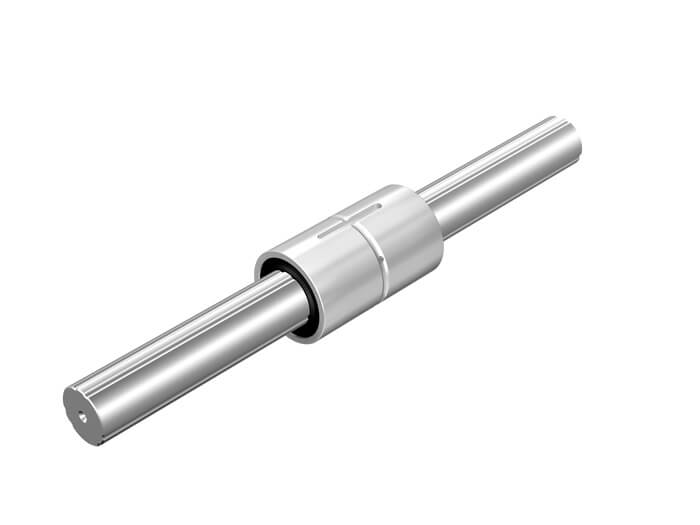

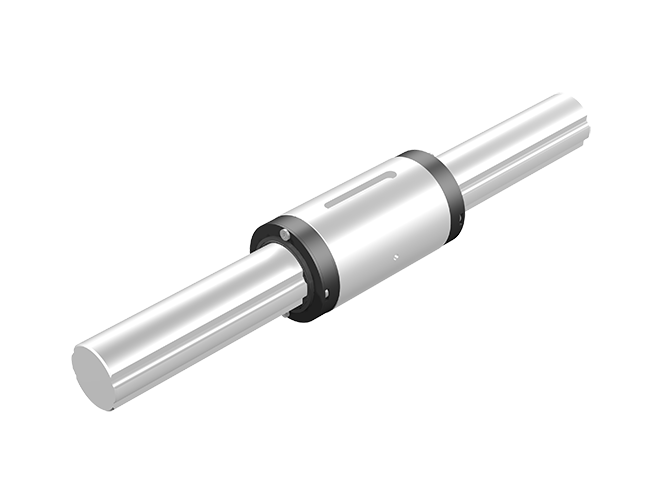

High Torque Model LBS

Model Number(s)

LBS, LBF, LBH, LBST, LBR

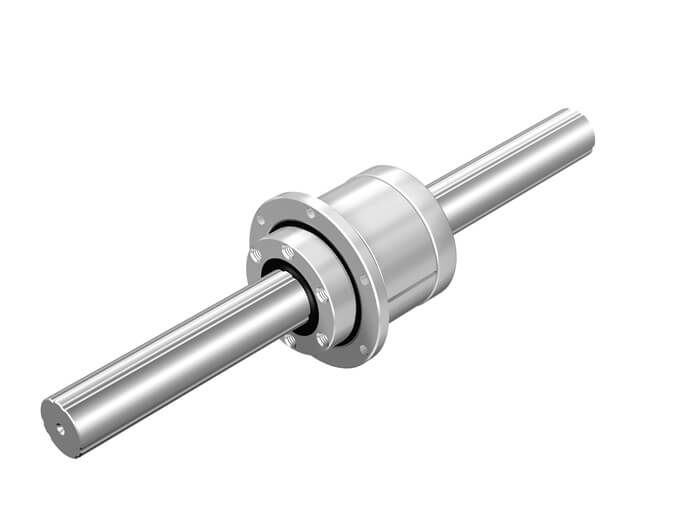

Medium Torque Model LT

Model Number(s)

LT, LF

Rotary with Gears Model LBG

Model Number(s)

LBG, LBGT

Rotary Model LTR

Model Number(s)

LTR, LTR-A

High Torque Caged Ball Spline

Model Number(s)

SLS, SLS-L, SLF

High Torque Type Ball Spline

Model Number(s)

LBS, LBST, LBF, LBR, LBH

Medium Torque Type Ball Spline

Model Number(s)

LT, LF, LT-X, LF-X, LFK-X, LFH-X

+27 (0) 11 453 1740

+27 (0) 71 896 2550

contact@dcauto-motion.co.za

This website uses cookies to improve your web experience.