A machine’s moving parts can be classified as rolling, linear, or a combination of both. With the development of rolling bearings about 110 years ago, rolling contact became the standard method for accomplishing rolling motion. This brought about a great technological revolution. Rolling contact not only saved motion energy, but also kept frictional resistance to a minimum and thus greatly improved the performance of machinery. However, even though a similar development in the field of linear motion would have been ten times as valuable, linear motion through rolling contact was a long time in coming.

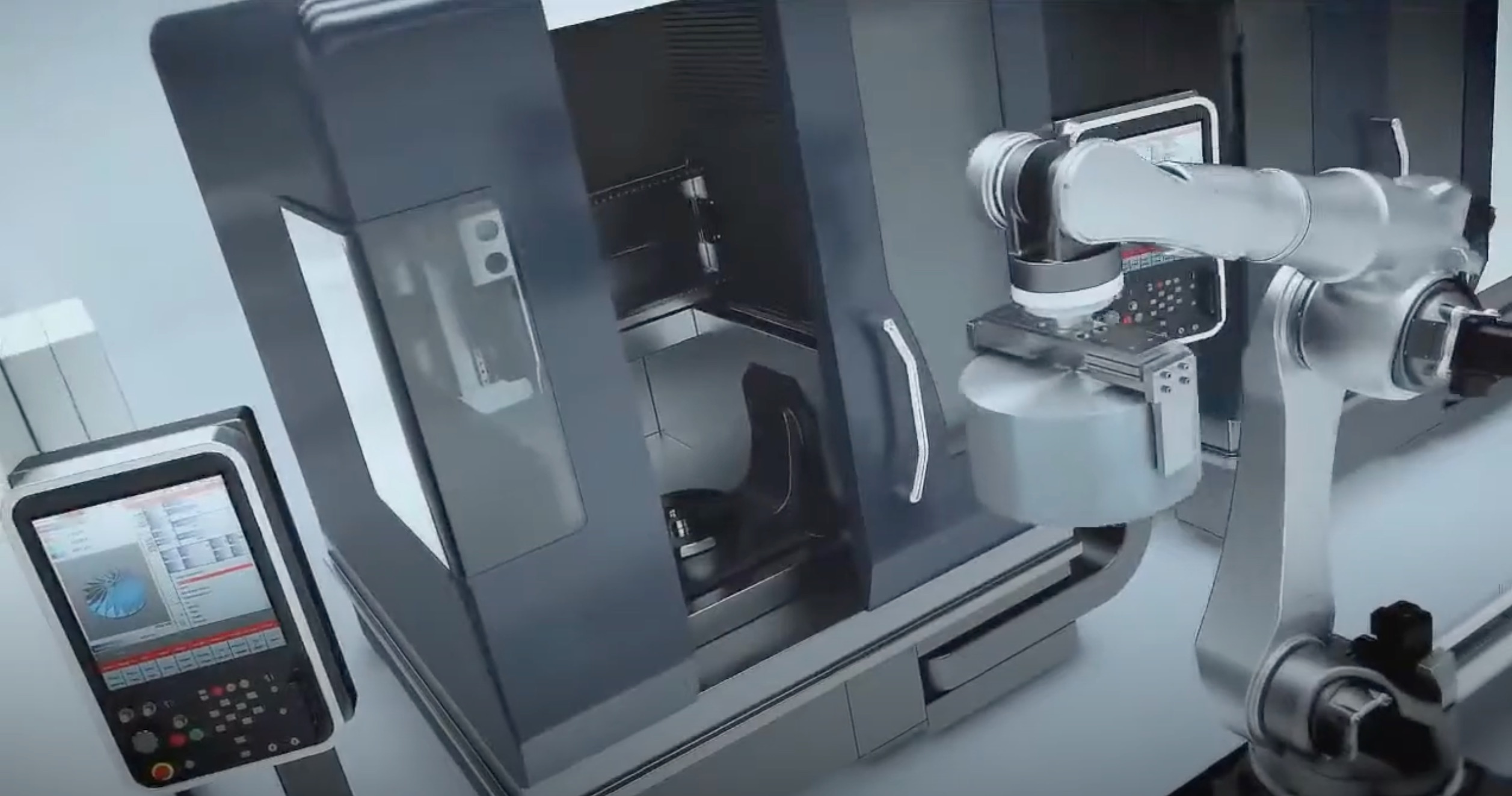

THK solved the problem, previously considered too difficult, of linear motion with rolling contact by applying its unique technological capabilities, and in 1972, it became the first company in the world to develop and commercialize the Linear Motion (LM) Guide. Our linear motion system enabled rapid improvements in the accuracy, speed and labor-saving potential of advanced mechatronic instruments. With THK’s LM Guides, machine tools and industrial robots become capable of ultra-precise operations, and semiconductor-manufacturing devices can operate in submicron units. More recently, the system has been applied in liquid crystal manufacturing lines, railway carriages, assistive vehicles, medical equipment, skyscrapers and residences, and amusement devices. The use of LM Guides has truly expanded beyond all prior boundaries.

Products

LM Guides (Linear Bearing Guides)

The LM Guide (Linear Bearing Guide) is one of our main products. It provides a component that enables linear rolling motion for practical use. When originally manufactured it was first in the world. It significantly contributes to the development of high-precision, high-rigidity, energy-saving, high-speed machines that benefit from extended service life.

Ball Screws (Precision & Rolled)

The Ball Screw is a high-efficiency method of converting rotary motion to linear motion by using a recirculating ball mechanism between the screw shaft and the nut. Compared with a conventional sliding screw, the ball screw requires driving torque of one-third or less, making it ideal for saving drive motor power.

Cross Roller Guides

The Precision Linear Pack is a superbly thin and lightweight recirculating ball linear guide. The main body is manufactured from precision formed plate which is heat treated and ground to provide a basis of this cost effective highly accurate guide.

Linear Actuators

The LM Actuator comprises an aluminium base combined with an LM Guide system, a top table and different drive types. This model offers a wide choice of options to suit any application.

LM Guide Actuator

The LM Guide Actuator is a compact actuator with high rigidity and high precision that has an integrated LM Guide with a ball screw. Reductions in the number of parts and design man-hours can be realised by adopting the LM Guide Actuator.

Cross Roller Rings

The Cross Roller Ring is a rotary roller bearing with high rotation accuracy. The cylindrical rollers are arranged to support loading in all directions.

Linear Bushing

The Linear Bush is a linear guide used in combination with a LM shaft that has a cylindrical shaft. This product makes linear movements with a minimum of frictional resistance to provide highly accurate and supple movement.

Ball Spline

The Ball Spline is a rolling guide spline bearing. This is an innovative product with a ball rolling on a groove connected to the shaft, realizing allowable loads greater than with linear bushing and enabling torque transmission while making linear movements.

Cam Followers

The Cam Follower is a compact bearing with a high-rigidity shaft and a built-in needle bearing. Most suitable as a guide roller for cam mechanisms and linear motion of automated machines and dedicated machines.

Lubrication Accessories

An assortment of lubrication associated products is available to maintain sufficient lubrication of machines.